Quality Assurance

EN 9100 Certification

WATT&WELL is certified in EN/AS/JISQ 9100:2017. This means the company is compliant with over 400 requirements, including:

- Project management

- Risk analysis

- Configuration management

- Consideration of special requirements and critical elements

- Special processes

- Verification and validation

- Surveillance of production

WATT&WELL complies with all those requirements while providing products that represent a cost and performance step-change to the aerospace industry.

The EN 9100:2017 certification has been granted by AFNOR. WATT&WELL is also a member of the online aerospace supplier information system. An online database of aerospace suppliers who are certified under the International Aerospace Quality Group rules are to comply with the 9100 standards series:

- AS 9100 (America)

- EN 9100 (Europe)

- JISQ 9100 (Asia)

Product Quality Assurance

WATT&WELL fulfills the product quality requirements in all project phases by following the quality management system standards and procedures. Design choices are made and justified according to customer specifications but are also in compliance with applicable standards (DO-254, DO-160, ARP4754A, ARP4761, ECSS). WATT&WELL can design equipment up to DAL A. The dependability team is able to run FMEA, FTA, and safety analysis, but also reliability analysis according to FIDES 2009.

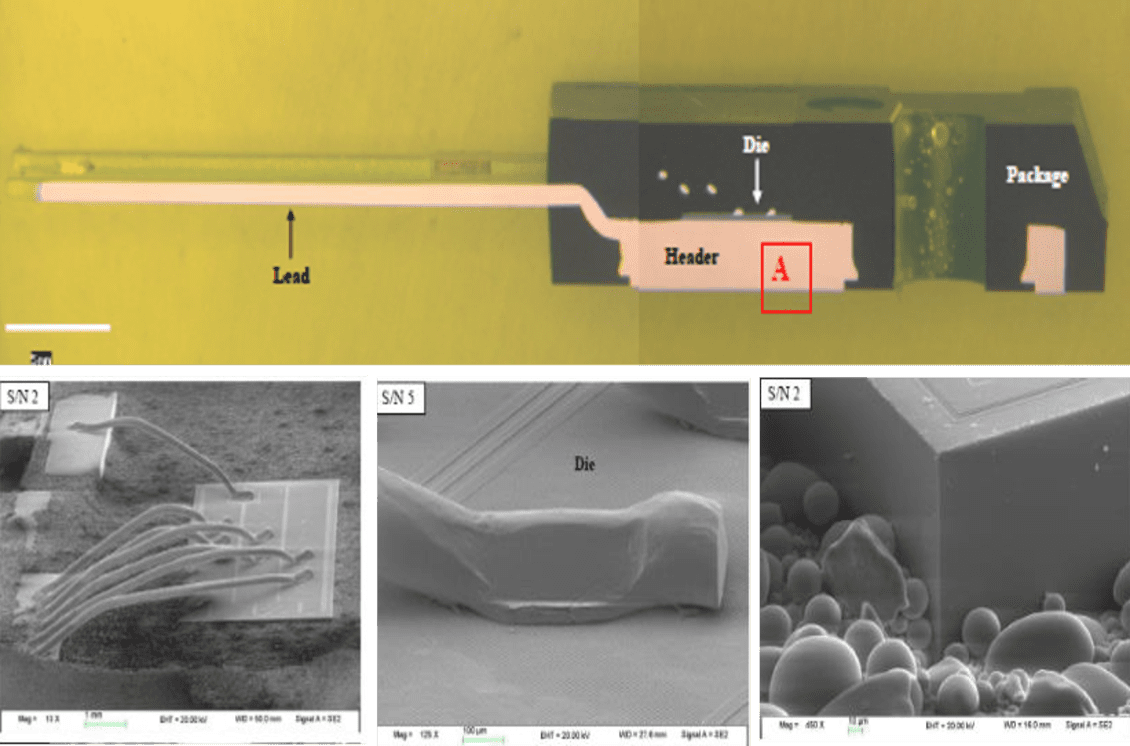

EEE Components & Technology Management Plan

Components and technologies are chosen according to the expected level of quality and ratings margin. A typical set of documents include a components and technologies management plan, construction analysis, Lead-Free Control Plan, obsolescence management plan, assembly justification file, component justification file, Part Stress Analysis, radiation hazard assurance analysis, PCB questionnaire, components obsolescence status, and a survey report.

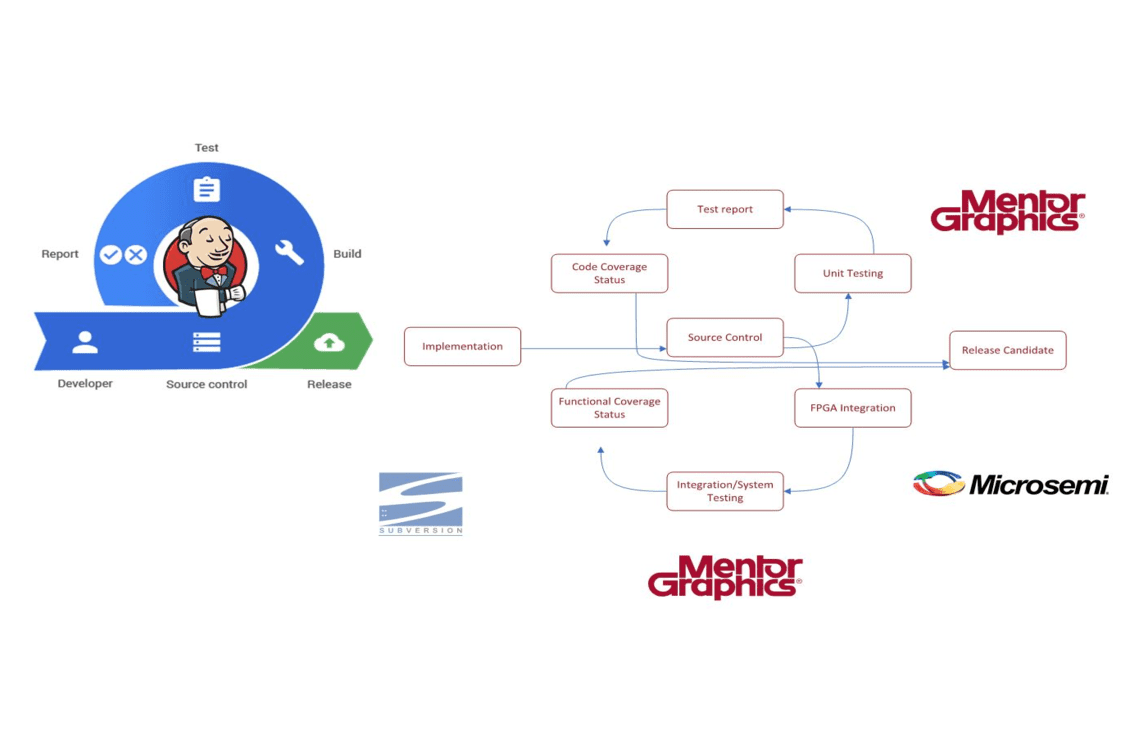

Software Quality Assurance

The in-house software and FPGA team is developed according to DO-178, DO-254, or ECSS standards. A continuous integration environment enables source control and verification (unit testing including the coverage and functional testing). Automated reports generation provides daily metrics, including coding/design rules check results, coverage results, unit test results, functional test results, and design performance reports.

Project Quality Assurance

Projects are managed according to our quality management system standards and procedures. A development plan is initiated and maintained during all project phases. It covers project planning, project organization, project breakdown structure, project review organization, but also requires management, risk and opportunity management, cost control, product and quality assurance, configuration management, and ethics and compliance.