Design—Hardware, FPGA, Software

The in-house WATT&WELL engineering team is able to develop the required hardware features and software or FPGA functions customized from existing building blocks or designed from scratch, if necessary. Typical hardware functions include local power supplies and latching current limiters, digital controllers, sensors and analog front end, power stage (including magnetics), and an EMI filter. Software and FPGA functions include data acquisition, communication stacks (Serial, CAN, Ethernet), control loops, FDIR, and modulation for power switches.

Prototyping

Prototyping allows fast, easier iterative work on the prototype to improve and debug it.

These capabilities include a network of agile and qualified partners, but also an in-house workshop for board modification and repair and software prototyping that uses code generation. Produced proofs of concept are useful for early concept validation and system requirement maturation.

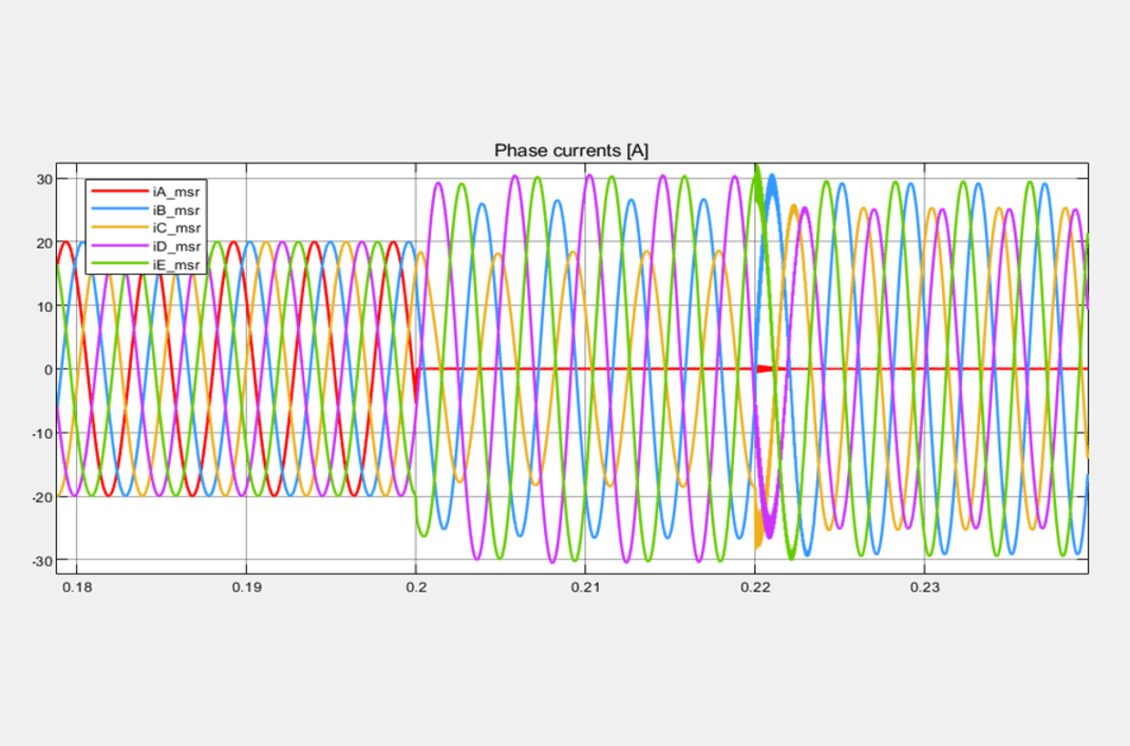

Simulation

Using Simulink, our control engineers are able to model electrical architecture or a part of it. They can simulate mission scenarios and verify that the proposed architecture and equipment meet the requirements. Our simulations include stability studies, motor drive performance analysis, power consumption evaluation, or any other critical characteristics of the specific system.

Industrialization

The in-house industrialization team works concurrently with the development team, providing MCAD and ECAD but also offering methods to achieve all the project’s requirements: functional, reliability, testability, manufacturability, and cost.

Qualification

The in-house instruments allow us to run tests and pre-qualifications: functional, thermal and humidity, conducted, and near field EMC. Other qualification tests are run at a partner’s facility.

Production

WATT&WELL has already qualified a sub-tier Electronics Manufacturer Service (EMS) for the aerospace series manufacturing. In this industrial organization, WATT&WELL is in charge of sourcing parts, specification of processes, approval of procedures, validation of processes, and product acceptance. EMS is responsible for the procurement of parts, incoming inspection, warehousing, assembly, and test implementation.

Test Benches

WATT&WELL is capable of designing and implementing test benches. These test benches include power supplies, loads, instrumentation, and automation by scripting.

Support

WATT&WELL’s role continues well after product delivery. The aftersales service team is always available to follow up with any inquiries and requests. Because some products and tools are to be maintained for decades, WATT&WELL encourage customers to maintain their equipment in qualified condition. This effort includes obsolete parts tracking, strategic stocks, or re-design.