Technologies

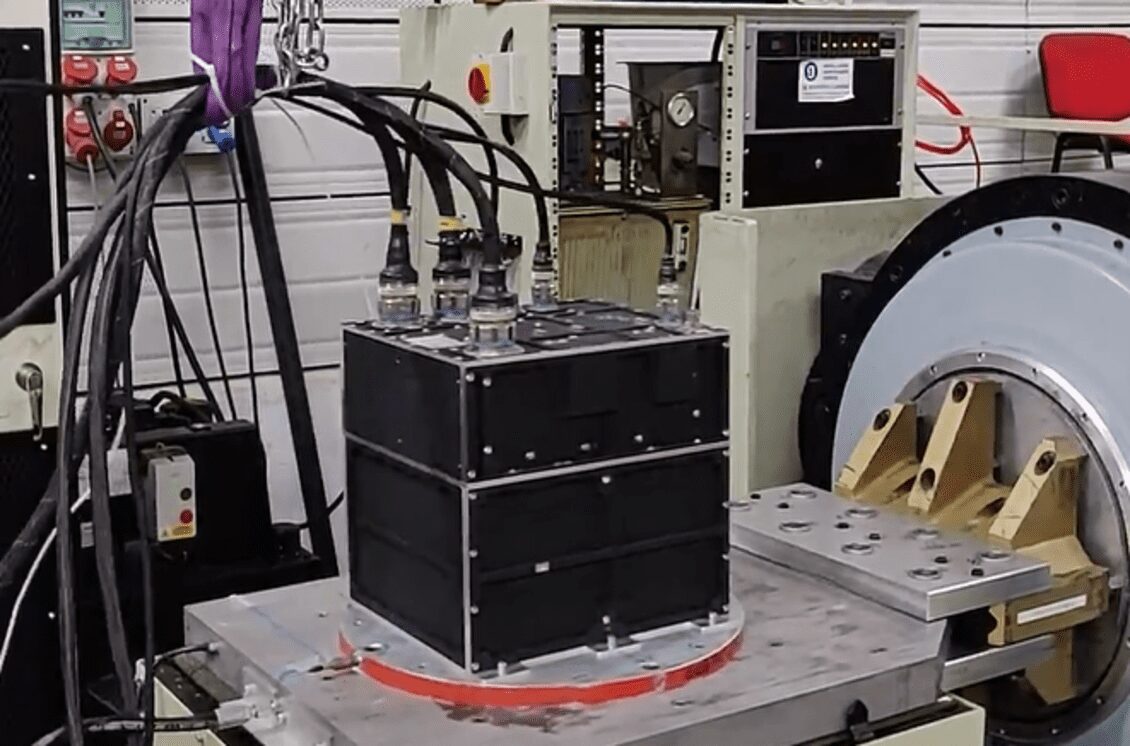

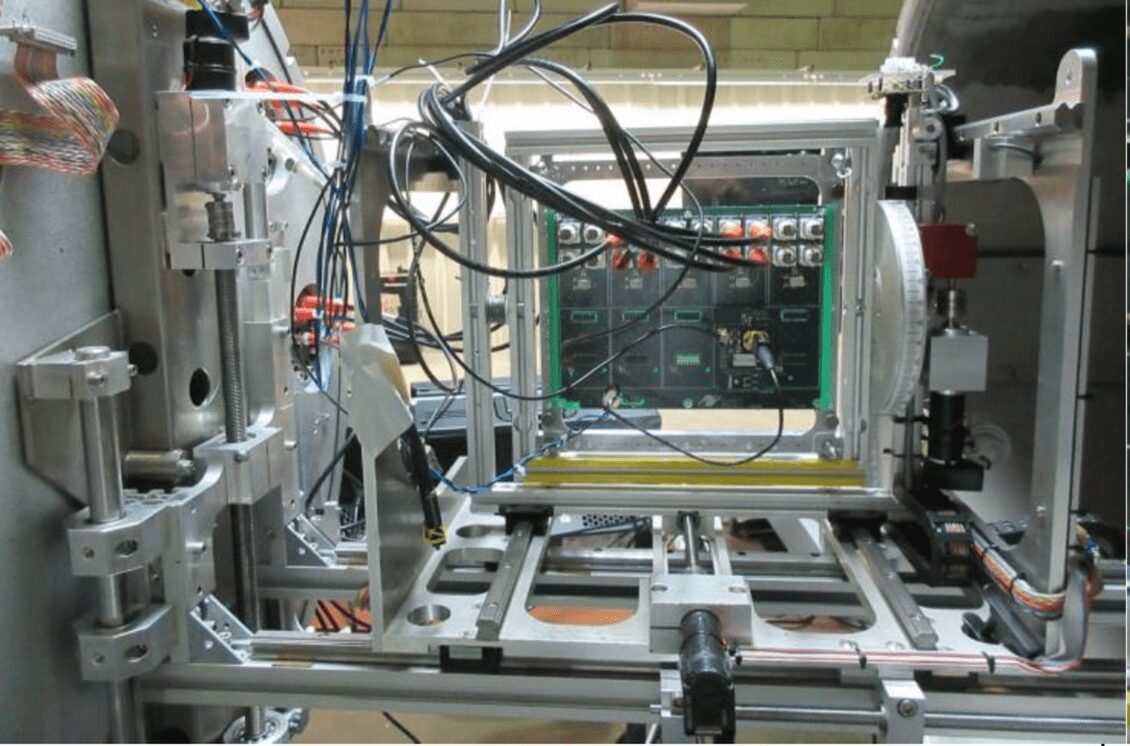

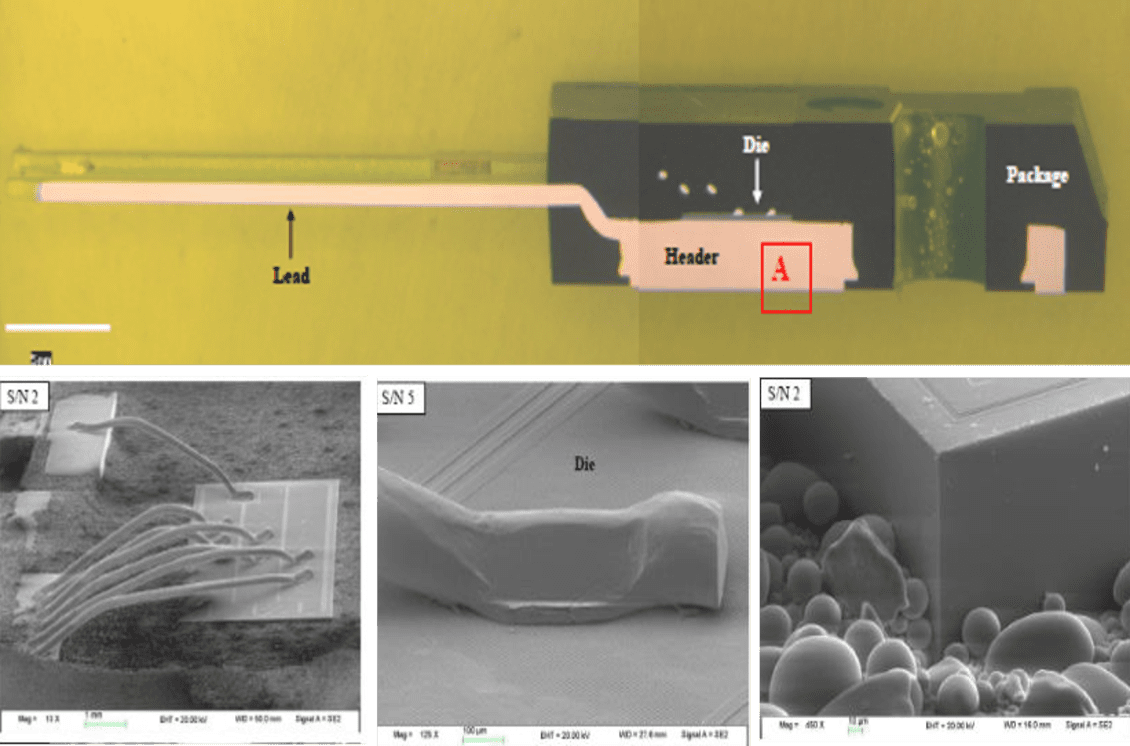

Electronics Racks for Shock & Vibration

Shock and vibration ruggedization are in the DNA of WATT&WELL since the company’s creation because Oil&Gas downhole electronics handle large levels of shock and vibration. The engineering team has designed aerospace electronics racks, including magnetics and PCB assemblies resisting extreme shock and vibration levels without failure.

Radiation Tolerant Components & Modules

An efficient way to lower the recurring cost and lead time of embedded space electronics is to design rad-tolerant modules. The idea is to avoid, when possible, the use of rad-hard components, preferring standard off-the-shelf components. WATT&WELL develops and maintains a database of industrial and automotive components that are tolerant to radiation, knowing their behaviors and limitations. Functions and modules are designed accordingly (using redundancy, latching current limiter, filters, etc.).

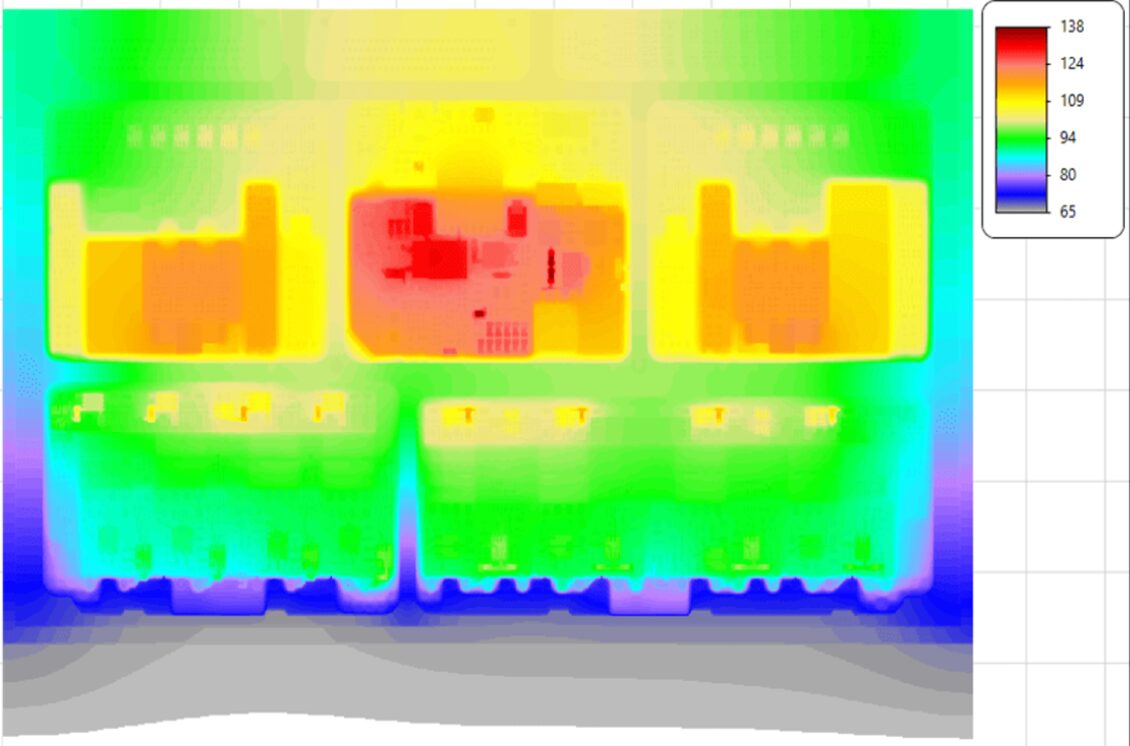

System Thermal Management

System integrators require high power density. As the components’ reliability is directly related to their temperature; thermal management is a key aspect of converter design. WATT&WELL can accurately estimate and measure the losses of a power converter. The best cooling method is selected to extract heat from the power components. These methods involve air or water cooling, radiative cooling, and conduction (including heat pipes). WATT&WELL is able to provide a thermal model and loss profiles during equipment missions and iterate with the system integrator.

Wide Bandgap Switches

WATT&WELL has acquired a deep experience in Silicon Carbide MOSFETs integration, starting in 2010 with high-temperature downhole electronics and next in e-mobility ultra-fast chargers. The technology is now mature enough, and WATT&WELL is now extensively using it in aerospace converters. The benefits are the low losses, even at high voltage/high frequency, the high operating junction temperature, and good behavior are under radiation. However, the high voltage transient generated by such devices implies caution with EMC aspects, especially common mode currents. The EMC filter design know-how enables WATT&WELL to use the last switches technologies that are compliant with the EMI aerospace level (DO160/ECSS).